Products

3D printing

3D printing in FDM technology

› Functional prototypes

› Series parts in small quantities

› Production tools

› Templates

› Assembly jigs

Advantages of FDM technology

› The thermoplastics used are resistant to mechanical and environmental influences

› Complicated constructions and cavities are no longer a problem

› Low cost compared to machining

› Complex geometry is no problem for FDM

Layer height: “Draft” 0.30 mm (pattern speed); Printing time: 15 min; Filament: PLA

Layer height: “Ultradetail” 0.05 mm = slow, accurate; Printing time: 4.30 h; Filament: PLA

3D Printer

3D printing using FDM method with a world leading industrial quality printer.

Build volume: 250 x 210 x 210 mm / 9.84*8.3*8.3* inches (for larger parts, there is a possibility to print in pieces and then glue).

-

- 0,05 mm Ultradetail

- 0,07 mm Ultradetail

- 0,10 mm Detail

- 0,15 mm Quality

- 0,15 mm Speed

- 0,20 mm Quality

- 0,20 mm Speed

- 0,30 mm Draft

-

- high stability

- high abrasion resistance

- good chemical resistance

- tensile strength is 33 N/mm²

- modulus of elasticity at 2200 N/mm²

- temperature resistant up to 108°C

- waterproof

PLA, PET, ASA, PC, ABS, HIPS, PP, TLEX

-

- Medicine

- Functional and product samples for automotive and mechanical engineering

- Architecture

- Prototype construction

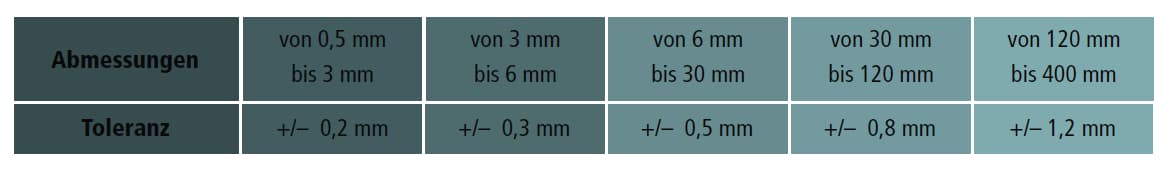

Manufacturing tolerances according to DIN ISO 2768-c

Product groups

Technical plastic molded parts

Busbar support

Supporting insulators 1-3 kV

Certified product quality

We produce in Germany under DIN standard. Our production offers the highest standards.