Construction

In-house design

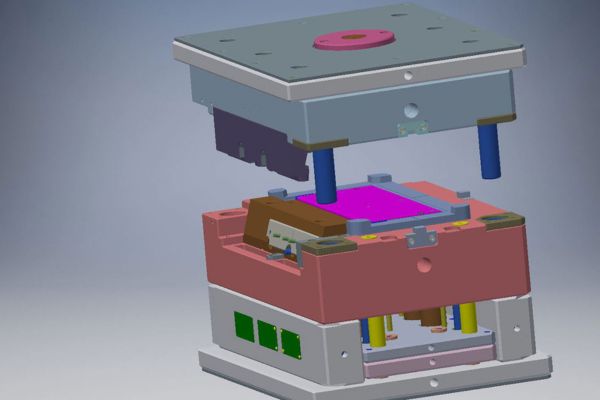

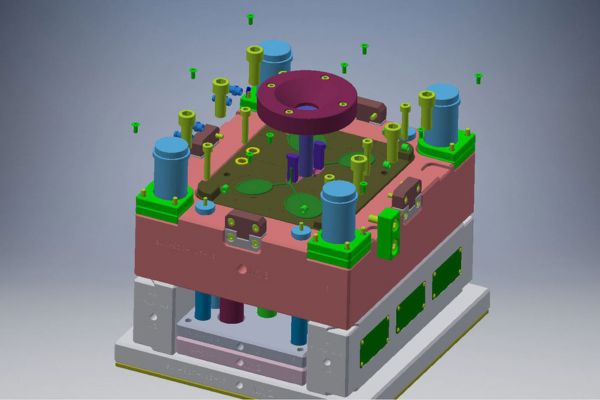

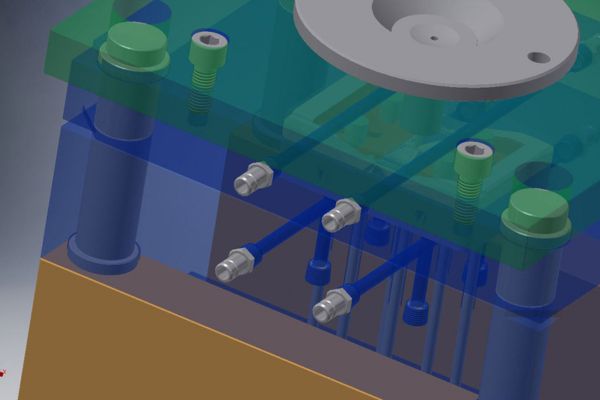

In our design 3D files can be customized. In most cases, the first designs are without demolding bevels, which are necessary to be able to remove the injected article from the “tool” or mold. These adjustments are of course also part of our services.

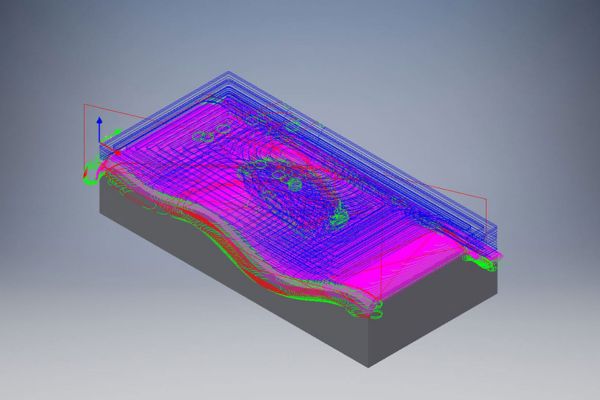

It often happens that only an old 2D hand drawing is available. In these cases we take the data from the drawing and create a 3D article in a common format e.g. as a .step file. With the help of this file, the design department can initiate further work steps, such as the creation of a tool design or a machine program using the CAM software Inventor 2017 and CAM iMachining. Subsequently, the article can be manufactured on our modern 5-axis machining centers.

Parts up to a size of 600 mm x 900 mm and 800 kg can be machined on our machining centers. Furthermore, we have a CNC lathe with two driven tools for radial machining in one clamping up to a diameter of 200mm.

Product groups

Technical plastic molded parts

Busbar support

Supporting insulators 1-3 kV

Certified product quality

We produce in Germany under DIN standard. Our production offers the highest standards.